Automatic Hydraulic Mounting Press with Fully Programmable HMI Touch Pad interphase for HOT mounting of samples in phenolic powder.

METLAB Labpress 40

Description

Fully Automatic Hydraulic Mounting Press

Cut materials and irregular samples need to be mounted in a plastic material so that surface can be ground and polished to reveal surface structure or to produce a flat parallel surfact for hardness measurement. The two usual methods of mounting samples are to use cold mounting resins or to use resins which can be moulded at elevated temperature and pressure. The hot compression mounting process can be carried out with the Labpress 40P. It is preferred to cold mounting for the following reasons:

(i) The method produces parallel sided block which is necessary for hardness measurement.

(ii) A moulded block is produced in a rapid time of say 10-15 minutes as compared to cold mounting.

(iii) Hot compression mounting does not need to be done in a fume cupboard.

(iv) The generally used phenolic mounting resins are very economically priced as compared to many cold curing resins.

The Labpress 40P is an advanced Mounting Press with automatic pressure and temperature cycle for compression mounting of samples in a range of thermosetting plastics. It is a compact bench top unit with integral hydraulic pump. Data on the moulding parameters are entered on a keypad and this information can be stored as a program for repeated use.

Construction

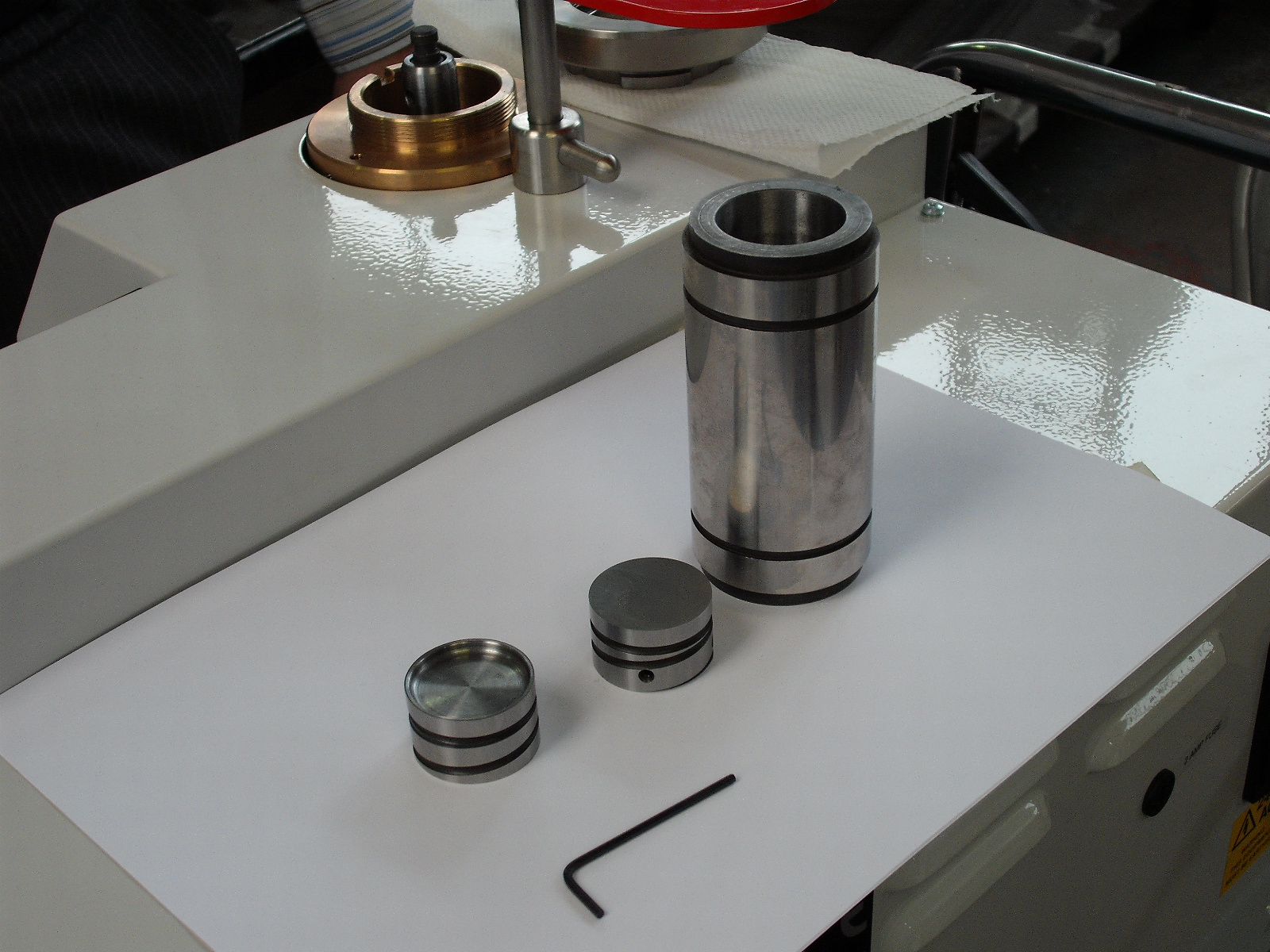

The hydraulic system comprises a compact integral pump acting on a 50mm cylinder which is used to amplify the pressure being applied to the lower piston in the mould. A pressure adjuster is located inside the cabinet. It is factory set and generally does not require adjustment for moulding full range of thermosetting resins. The lower piston is shaped so that the mould (containing the sample) has bevelled edges to avoid tearing the polishing cloths. The upper piston in the mould is removable so that the samples and thermosetting resin can be introduced.

The moulding time and temperature are inputted on the keypad. Both parameters can be set for the required auto moulding cycle. A water inlet and drain is located on the rear panel so that the mould can be rapidly cooled after the cycle. The moulding cycle is activated by calling up a stored program.

The moulds are interchangeable and this machine can be rapidly converted to produce a different block diameter. Three metric mould sizes 25, 30, 40mm diameter and three inch mould sizes 1in, 1 1/4in, 1 1/2in diameter are available. The moulds are supplied complete with matching pistons and locate in a surrounding conducting block. 4/250 Watt cartridge heaters and cooling water channels are embedded in this block for rapid heating or cooling of the mould.

-

Specifications

- Mold Closure:

- Cap holding top piston, locks with bayonet fitting, sealing mold.

- Hydraulic Pressure Unit:

- Compact Hydraulic Pump and Controller to Adjust Pressure; (in bar) Intermediate cylinder moving lower piston out of mold. Pressure Safety Valve

- Molding Pressure:

- Up to 6000 psi (Mold 1.25″)

- Heater Block:

- Incorporates 4/250 W Heater Cartridges with fuses for Overtemperature Protection.

- Temperature Controller:

- Temperature can be set up to 250° C or 480° F; K Type Thermocouple

- Timer:

- Digital Timer can be set to count down, 0-60 minutes.

- Cooling:

- Cooling water channels in heater block connected to supply through a solenoid water switch.

- Dimensions:

- Width: 14″ (355mm)

- Depth: 16″ (400mm)

- Height: 15″ (380mm)

- Weight:

- 66 lbs. (30 kg)

- Mold Closure:

Reviews

There are no reviews yet.