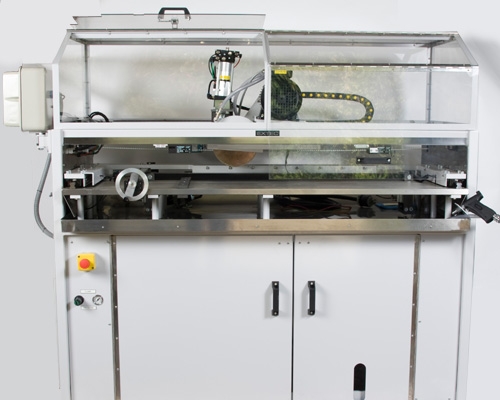

The Labcut® 5000 Series Advanced Precision Composite Plate Saw is built for precise cutting of composite materials for preparation of highly accurate composite test specimens.

METLAB Labprep 5000

Description

The Advanced Metlab Technologies Labcut® 5000 Series features two standard models accommodating for the cutting of 2 foot by 2 foot and 4 foot by 4 foot composite sheets with maximum thickness of 0.75″ (~20 mm). Customized special order units can accommodate maximum thickness of 1.5″ (~40 mm).

All units include an EZ-TSK (Touch Screen Keypad) for simple user operation.

Features:

- Main frame with slatted work table

- Internal recirculating coolant system

- Cutting head with variable speed traverse

- Precision fence mechanism for accurate width cut

- Control module includes an EZ-TSK

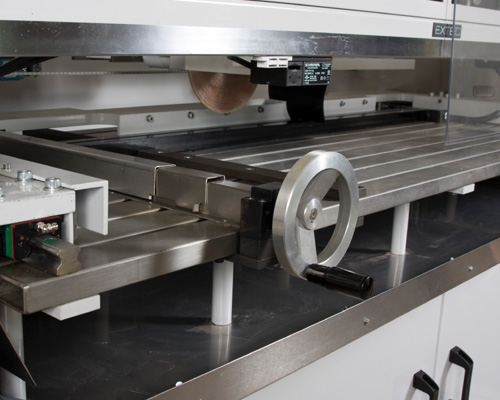

The main frame construction has a flat stainless steel slatted worktable with stainless drip tray immediately below it. A small insert table is located at one end of the worktable so the small pieces of material can be handled more easily. The width of the table is made to accommodate the width of sheet being sectioned

Pneumatic Sheet Clamps

For accurate sectioning the composite sheet need to be firmly clamped during cutting. For this purpose pneumatic clamps are fitted to the worktable the entire length of the cutting head traverse. The clamping surfaces are rubberized for improved clamping of long sheets

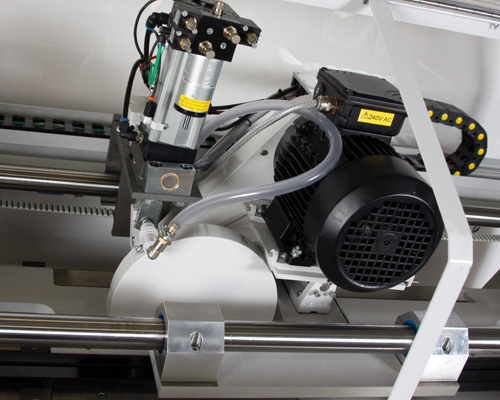

Cutting Head Traverse

With the Metlab Technologies Labcut® 5000 Series Advanced Precision Composite Plate Saws the cutting head moves accurately along linear bars so that the alignment of the cutting wheel to the material fence and wheel slot is crucial for accurate parallel sections.

The cutting head is powered by a 3kW/4hp motor. It can be automatically raised or lowered to take account of thickness and depth of cut. The material is clamped to the work table with pneumatic clamps on both sides. Coolant jets are positioned inside the wheel guard on either side of the wheel to spray coolant on the cutting area.

- Automatic raise/lower of cutting head position

- Cutting head traversing on linear bars for accuracy

- Cutting head motor 3kW/4hp

- Coolant jets incorporated into wheel guard

- Cutting head traverse speed is variable (requires inverter) via the EZ-TSK

- More Accurate Fence Mechanism

Fence has been designed for precision accuracy over the longest cut lengths, moving along linear bars.

Fence position control via EZ-TSK

Pneumatic lock for a stable fence position during sectioning

Control Module Design

- Cutting machine operation controlled from EZ-TSK

- Digital readout of fence position to 0.1mm

- Optional wheel speed variation can be operated from EZ-TSK